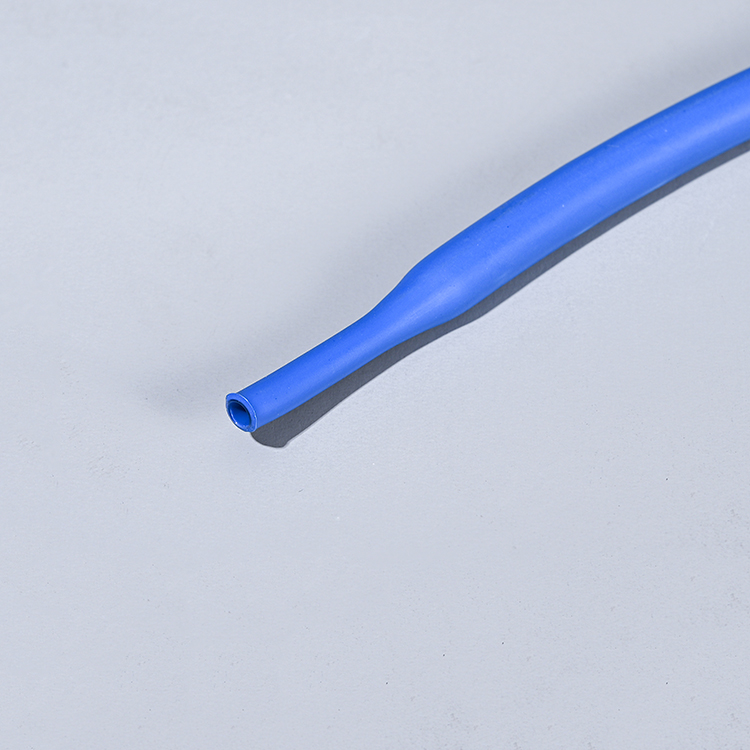

Our fluorine heat shrinkable tube is a high temperature resistant transparent flame retardant heat shrinkable sleeve, composed of polyvinylidene fluoride (PVDF) material, made of irradiated cross-linked special fluorine polymer, with excellent chemical resistance and solvent resistance, good toughness and semi-hard, thin-walled and light heat shrinkable tube, especially suitable for high temperature resistance and the need to resist abrasion and high mechanical performance requirements of the environment, such as aerospace, radar, locomotive and other wire and cable connections and electronic components of the insulation protection, stress relief and the identification of the covered components.

PVDF characteristics: shrinkage ratio 2:1, semi-hard, thin-walled insulation, excellent flame retardancy, high temperature resistance 175°C , good toughness, excellent wear resistance and chemical resistance , compliant with RoHS, REACH environmental regulations

Operating temperature range: continuous use temperature: -55°C to 175°C , minimum starting shrinkage temperature: 155°C , minimum complete shrinkage temperature: 175°C

Conformity: SAE AMS-DTL-23053/8, UL224 , VW-1

Performance indicators:

|

Performance

|

Indicator requirements |

Test Method |

Typical values |

|

Radial shrinkage (%) |

≥200% |

ASTM D 2671 |

200% |

|

Tensile strength |

34.5 MPa min. |

ASTM D 638 |

≥45MPa |

|

Elongation at break |

150% min. |

ASTM D 638 |

≥300% |

|

Elongation at break after ageing |

50% min. |

ASTM D 638 |

≥200% |

|

Thermal shock (300°C, 4 hours) |

No cracks |

ASTM D 2671 |

No cracks |

|

Low temperature flexibility (-55°C, 4 hours) |

No cracks |

ASTM D 2671 |

No cracks |

|

Insulation withstand voltage and breakdown |

2500V, 60sec, no breakdown |

ASTM D 2671 |

No breakdown |

|

Volumetric resistivity |

1013Ω·cm min. |

ASTM D 876 |

≥1013Ω·cm |

|

Corrosive |

Non-corrosive |

ASTM D 2671 |

Non-corrosive |

|

Flame retardancy |

VW-1 |

UL224 |

By |

|

Longitudinal shrinkage (Φ0.8-Φ6.4) |

≤5% |

Ovens |

97% |

|

Longitudinal shrinkage (Φ7.9 - Φ25.4) |

≤7% |

Ovens |

93% |