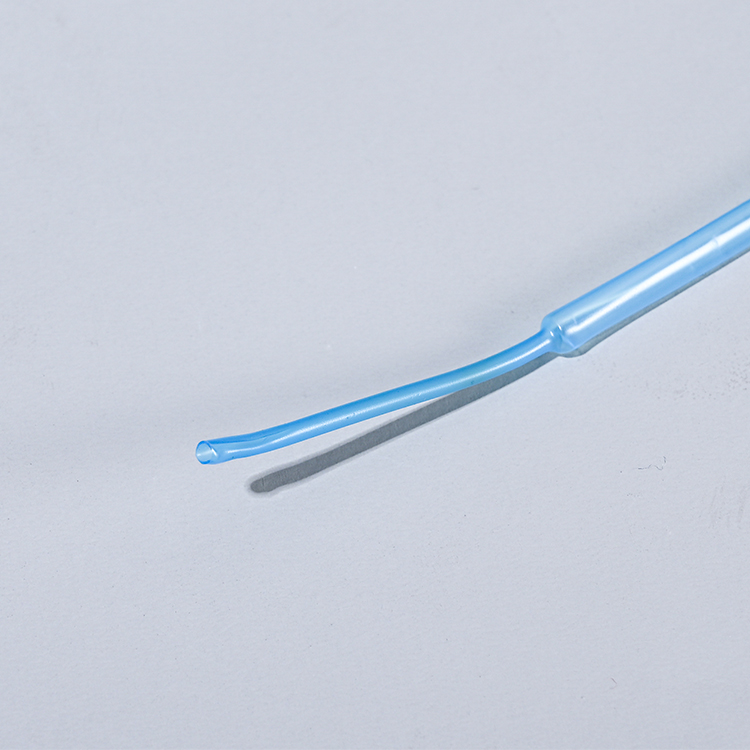

The heat shrink tube industry often refers to double wall heat shrink tubing as double wall tube, also known as heat shrink tube with glue, heat shrink tube with glue, waterproof heat shrink tube. This is because of the performance characteristics of the double-walled tube: the inner wall with hot melt adhesive, the outer layer is heated to shrink, the hot melt adhesive softens and flows, can completely wrap and bond the wire harness or other items, after cooling and curing, thus has excellent sealing and waterproof performance.

Performance: High temperature shrinkage, soft and flame retardant, insulation and corrosion protection. Widely used for insulation protection of various wire harnesses, solder joints, inductors, rust and corrosion protection of metal tubes and rods, etc. Voltage level 600V.

Polymer materials go through a glassy state and a highly elastic state as the temperature goes from low to high, with properties close to plastic in the glassy state and rubber in the highly elastic state.

Use: The heat shrink tube is heated to a high elastic state during production, a load is applied to make it expand, it is cooled quickly while remaining expanded to bring it to a glassy state and this state is fixed. As soon as it is heated during use, it changes back to the high elastic state, but then the load is gone and it has to retract.

Shrinkage ratio: 2:1

Shrinkage temperature: 84°C~120°C

Operating temperature: -55℃~125℃

Fire Rating: VW-1

Heat shrinkable sleeving has excellent flame retardant and insulating properties, very soft and elastic, low shrinkage temperature, fast shrinkage, and can be widely used for wire connection, wire end treatment, solder joint protection, wire harness marking, insulation protection of resistance and capacitance, corrosion protection of metal rods or tubes, protection of antennas, etc. Under the action of high-energy radiation, the linear polymer material forms a three-dimensional net-like cross-linked structure. The cross-linked polymers are greatly improved in terms of mechanical strength, temperature resistance, chemical solvent resistance and ageing resistance, especially in terms of acid and alkaline resistance.

Previous:Already the first article

Next:An introduction to the meaning and advantages of PVDF heat shrink tubing.